ARGUS Portfolio: Cost- Effective Monitoring of MV-LV Substations with Integrated WAN-Communications

Over the last years, the need for a 'Smart MV-LV Substation' has become obvious: monitoring (metering), detection of technical and non-technical losses, fault detection and localization, directional fault passage indication, measuring current (Voltage) before and after the transformer in the MV-LV substation, partial discharge detection on key assets, detecting short-circuits, and acquiring minimal power quality information is crucial. The WAN-communication of these parameters is, in most cases, through IEC 60870-5-104 communication, carried by a GPRS/3G/CDMA 450MHz TCP/IP data link to a SCADA master set-up. Bausch Datacom launches now a portfolio that offers a solution for deployments on a large scale.

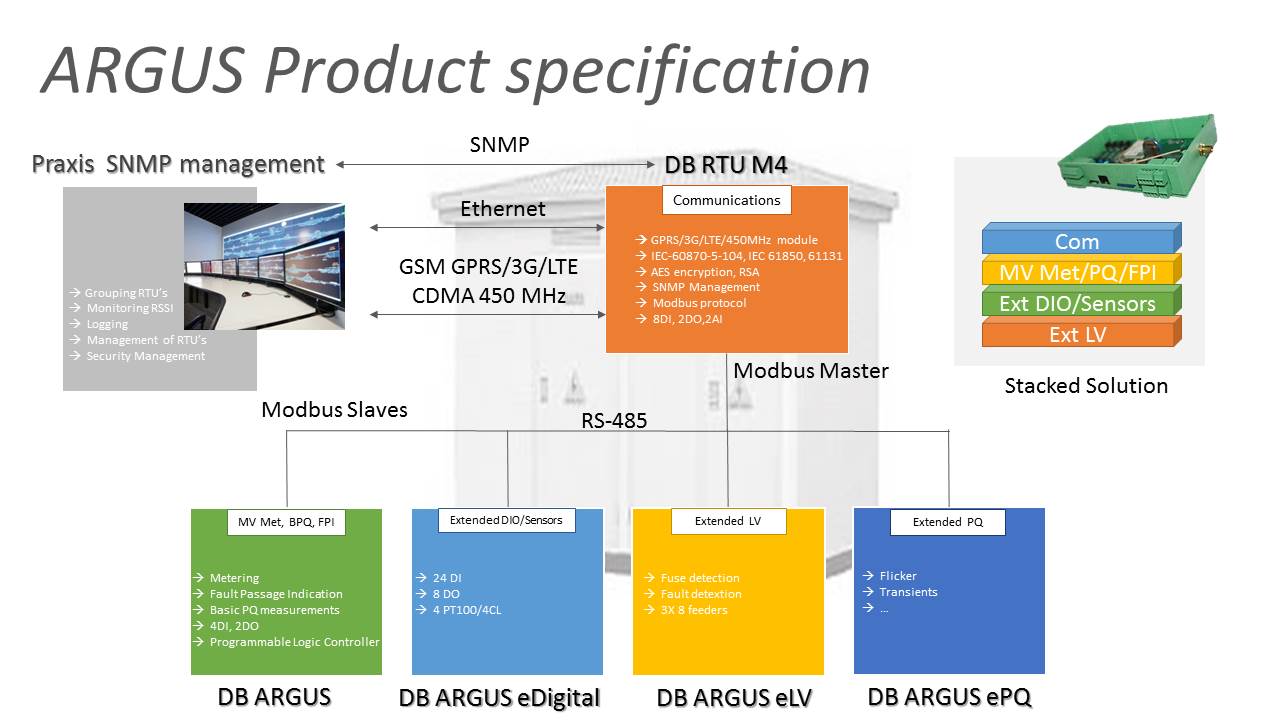

ARGUS will have communication, a basic Power Quality functionality, Metering and Fault Passage Indication features that can be extended through modules

Many DSO's in Europe have been confronted with the awkward need to improve their knowledge of their grid, both on the MV infrastructure (6-22 kV) as the LV infrastructure (230 V-400 V), to maintain their quality of service in the face of the EU policy-driven, accelerated adoption PV, heat pumps, and electric vehicles. The big challenge is to integrate devices that are capable of measuring the needed parameters, that can be fitted in small cabinets, and, last but not least, are affordable! Given the large-scale roll-outs required, cost is often the limiting factor.

Based on information of DSO's such as Gas Natural Fenosa (Spain), EDP (Portugal), Eandis (Belgium), Sibelga (Belgium), and Alliander (Netherlands), it is clear that there is a common core of measurements that needs to be retrieved and analysed from the grid. Especially at the key link between the MV and the LV infrastructure - the MV-LV substation -. there is currently a lack of data. Awareness of real-time load levels, losses, load limits, faults, and,, in some cases, detection of partial discharges in the transformer and switch gear areas can greatly help in the exploitation and fault recovery of the distribution system., To enable accurate measurements on medium-voltage, for instance to determine the voltage profile, power quality indices, and enable accurate directional fault passage indication, a novel Voltage sensor, integrated with the MV cable is also part of the portfolio. It is highly compact, and offers great cost advantages over traditional sensors, and can be retrofitted in many cases. To be able to allow DSO's in Europe (and worldwide) to finance an adequate Power Quality and reliability strategy for the medium-voltage and low-voltage infrastructure, Bausch Datacom aims at a tailor-made portfolio of hardware and software that provides these core features.

Many DSO's in Europe have been confronted with the awkward need to improve their knowledge of the operational state of their grid, both on the MV infrastructure (6-22 kV) as the LV infrastructure (230 V-400 V).

The ARGUS Portfolio

There is a plethora of academic research, as well as industry studies, such as the Dutch KRIS program, that produced consistent results concerning the root causes of grid disturbances, and the measures that the DSO need to implement to sustain the power quality of the European electricity grid. It is obvious that steps need to be taken to improve the grid operation to counter the many challenges of the liberalization and de-centralization of energy (electricity) production and transmission. Many DSO's try not to invest in more copper, which is the traditional approach to capacity and power quality issues, but aim at a more intelligent infrastructure. As a consequence, the KIC-InnoEnergy program identified key areas where the present-day technology was in some key aspect insufficient, and developed new approaches to overcome those limitations. Some of the results include a distribution-optimized Voltage measurement technology for the MV grid (15 kV at present, but scalable to all typical levels), acoustic partial discharge detection for buss bars and transformers , and directional fault passage indication (also applicable for high impedance faults in isolated-neutral grids). Regarding power quality - how stable is the typical supply of 230 V or 400 V for the customer? - There are many standardized( EN50160, IEC 61000-4-30...) ways to express this, but which parameters are crucial for the DSO? What needs to be measured?

Phenomena such as voltage distortions, variations, unbalances, flicker, dips, sags ... are difficult to interpret in relation to the topology of the infrastructure and load variability. An even more poignant question: why would a DSO measure imperfections in its system, thus implying a shortcoming in its primal task?

The answer to this question is probably that a typical DSO will try to find a solution which is affordable and beneficial to address the most urgent infrastructure issues in the shorter term, while planning long-term capacity upgrades to the system at a more nominal replacement cycle. To direct such short and long-term investment planning effectively, being aware of areas with present issues, and areas with future potential for problems can greatly help in this task. Also, by being aware of areas where the power quality is trending to the limits, effective scheduling of works can exactly prevent costly PQ shortcomings before they become noticed by the customers. Thus, the DSO gains the option to operate a more pro-active and precise asset management.

Bausch Datacom will integrate this approach in a cost effective solution that can be

deployed and fitted in secondary distribution substations (MV-LV). The aim is to introduce a basic product that allows communication (GPRS, 3G, LTE, CDMA 450 MHz) using a SCADA protocol, such as IEC 60870-5-104, and can interface - using Modbus over RS-485 - to modules performing the core functions, such as directional fault passage indication, metering and basic Power Quality indications.

ARGUS is an instrumentation portfolio that allows communication (GPRS, 3G, LTE, CDMA 450 MHz) using a SCADA protocol, such as IEC 60870-5-104, and which can interface - using Modbus over RS-485 - modules performing directional fault passage indication, metering and Power Quality indications.

The ARGUS Approach to Smart MV-LV Substations

In order to balance budgetary, logistic and functional challenges, the ARGUS portfolio

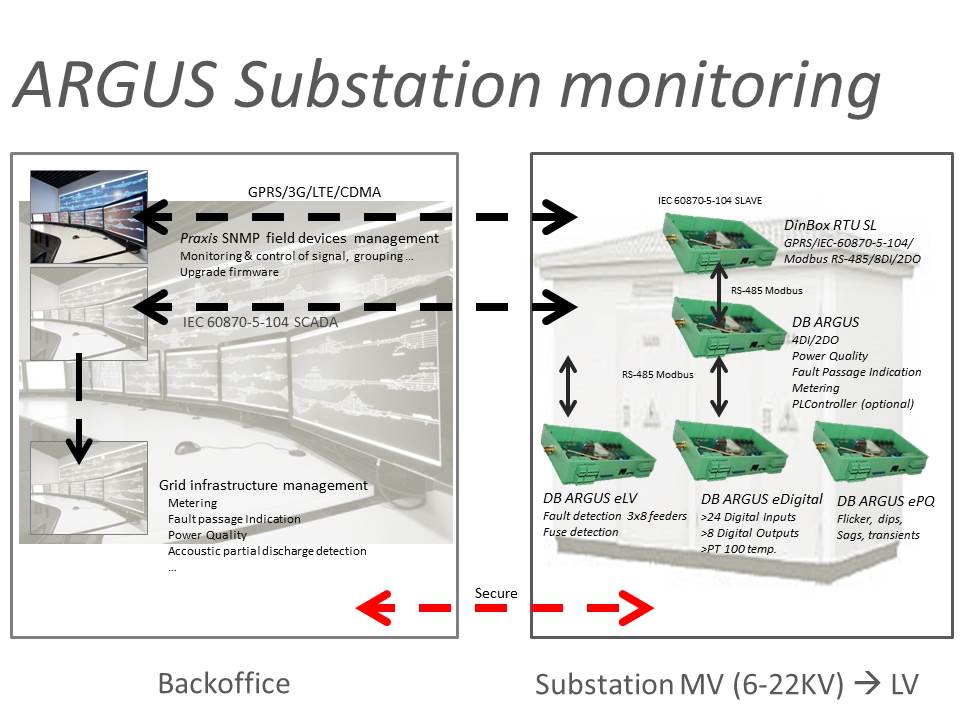

was designed from the ground up to be modular. The system is based on a main communication device - DinBox RTU M4 - which is a ‘stepping stone' unit that provides communication (GPRS, 3G, LTE or CDMA 450 MHz - Telit module approved by Liander and Stedin in Holland), protocols such as IEC 60870-5-104 slave and Modbus and a limited number of digital inputs and outputs.

This communication device is managed by the PRAXIS Modem Management Unit, meaning that the infrastructure of DB RTU SL RTU's can be grouped, monitored, configured, diagnosed, and firmware of the applications can be upgraded in a central manner.

The main module for the grid state measurements is the DinBox ARGUS which incorporates a minimum number of digital and analog channels to perform alarm functions (short-circuit, temperature, smoke, doors, and other monitoring), Directional Fault Passage Indication on MV, and energy and Power Quality measurements. This data will be sent/retrieved by the DinBox RTU M4 through Modbus and ‘mapped' to the IEC 60870-5-104 central SCADA

The DinBox RTU ARGUS can be extended by DinBox ARGUS eLV, providing many additional analog channels (for example for load profile monitoring and fuse state detection on each LV feeder individually), and by DinBox ARGUS eDigital, which provides digital inputs, outputs and PT100 interfacing (for example, to remote-control a motorized RMU). The main idea is to offer to DSO's a way to deploy basic functionalities on the large scale of the MV-LC substations, and use the modularity of the ARGUS system to scale each installation as changing operating requirements dictate now and in the future. As industry-standard busses are used within ARGUS, compatibility with already-installed and legacy equipment is possible in many cases.

Comments ( 0 )

Like

There are no comments yet